Product

Contact Us

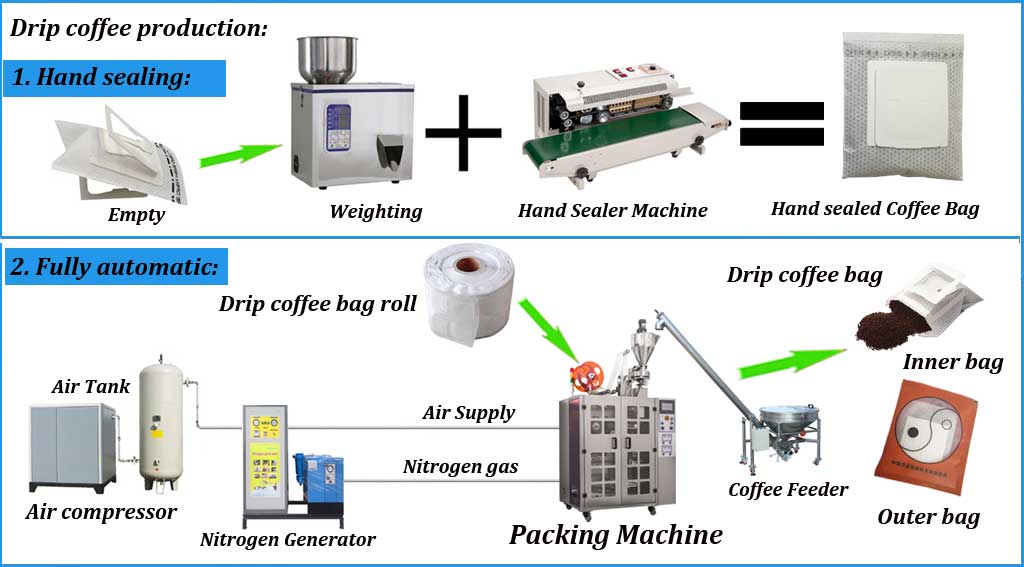

C19D ultrasonic sealing Drip coffee bag packing machine is suitable for drip coffee bag with outer envelope, available with ground coffee like Brazilian coffee, Guatemala coffee, Honduras coffee, Villa coffee and Arabica coffee, etc, and other small granule products - Deatiled pictures and Video.

A small note from professional manufacturer:

If you are looking for drip coffee bag packaging machine, please kdinly check parts below:

1. What is the packing weight or volume for drip coffee bag?

2. How many types of drip coffee filter bag are there?

3. What type of packaging materials is used for outer drip coffee bag?

4. How to brew the drip coffee bag?

5. What is the difference between heat sealing and ultrasonic sealing drip coffee bag packaging machine?

6. What is the packing for whole machine when shipping?

7. Do you need fill the Nitrogen gas generator?

7. Here shows the working video of drip coffee bag packaging machine.

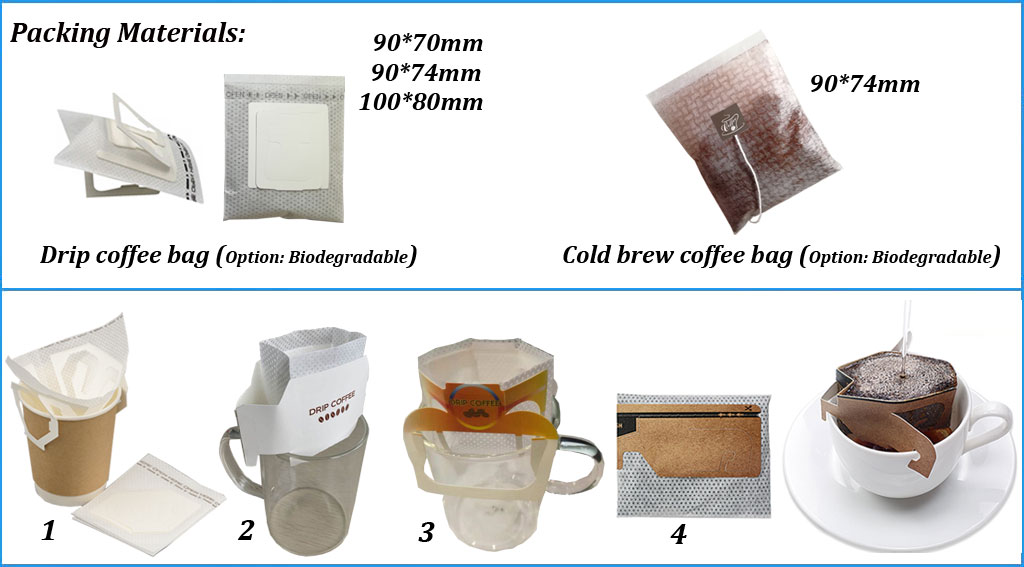

2. Type of drip coffee bag: People from whole world used drip coffee bag between 90*74mm and 90*70mm because the drip coffee bag materials is a kind of standard products for packing machine.

3. The packaging materials for outer bag is Kraft paper bag or PE bag with aluminum foil, For more details, please kindly contact us.

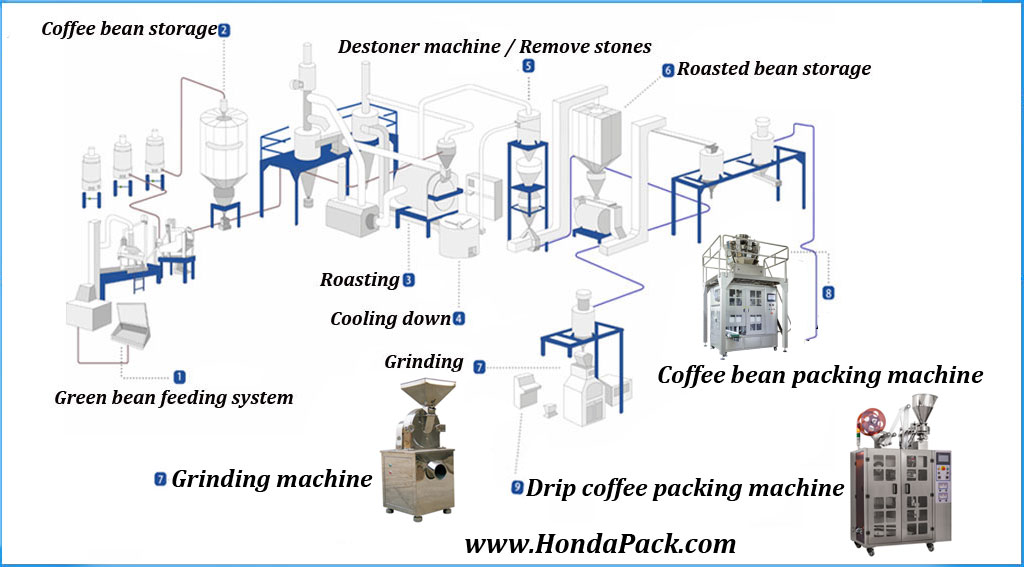

4. Here shows coffee production related.

5. The main difference between heat sealing and ultrasonic sealed drip coffee bag is in Sealing Edge of Inner bag. For more details, please kindly contact us.

6. The standard packing for shipping we used is the Plywood Case with plastic film wrapping inside:

7. Nitrogen gas generator: Can supply the Nitrogen gas so that can be inject into drip coffee bag to extend coffee shelf life and keep coffee fresh. For more details, kindly contact for more details.

8. Here shows the working video of drip coffee bag packaging machine: Except this video, welcome to click here to see more working video.

Feature of drip coffee bag packaging machine:

|

Type: |

Drip coffee packing machine Series |

|

Product model: |

C19D |

|

Product name: |

Ultrasonic Drip Coffee Inner and Outer Bag Packing Machine |

|

Bag type: |

3 side sealing |

|

Outer Bag size: |

L:85~120mm,W:75~100mm (Film width 200mm, Bag size: 120*100mm) |

|

Inner Bag size: |

L:50~75mm, W:50~90mm (Filter paper width 180mm, Bag size: 90*75mm) |

|

Packing speed: |

40~60 bags/min |

|

Filling range: |

5~15g; accuracy:≦±0.1g/bag |

|

Measuring: |

Volumetric cup |

|

Inner Packing material |

Drip Coffee Bag Filter paper; Nylon filter mesh |

|

Outer packing material |

Kraft paper/aluminum coating; PE/aluminum coating; PE film |

|

Sealing method: |

Ultrasonic sealing and cutting for inner bag; Outer Bag by heat Sealing. |

|

Power: |

Single phase, 220V, 50HZ, 1.5KW |

|

Weight: |

600KG |

|

Dimension (L*W*H): |

1200*900*1900mm |

Drip coffee bag packing machine:

This drip coffee packaging equipment is classic version, based on the following features:

1. Simple design and easy operation

1.1 Humanized design: It is type of machine that is easy to learn, and easy to handle, with reasonable design, intuitive and easy-to-understand operation interface, even if you are a first-time operators, you still can quickly get started. This design reduces training costs and time and improves work efficiency.

1.2 Modular structure: The equipment may adopt modular design for easy maintenance and trouble shotting. When thing came up, it can be quickly found and solved to reduce downtime and ensure the continuous operation of the production line.

2. Stable performance and strong durability

2.1 Mature technology: Classic version are often based on mature technology. After long-term market verification and user feedback, the performance is stable and reliable, and the failure rate is low.

2.2 High-quality materials: Made of high-quality parts to ensure that the equipment can still maintain good working condition under long-term and high-intensity use, extending its service life.

3. High cost-effectiveness

3.1 High cost-effectiveness: Compared with some high-end and complex equipment, the classic style of drip coffee packaging equipment is more affordable in price, while meeting basic production needs, and has a high cost-effectiveness.

3.2 Low maintenance cost: Due to the simple design and mature technology, the maintenance cost of the equipment is relatively low, reducing the operating costs of the enterprise.