Product

Contact Us

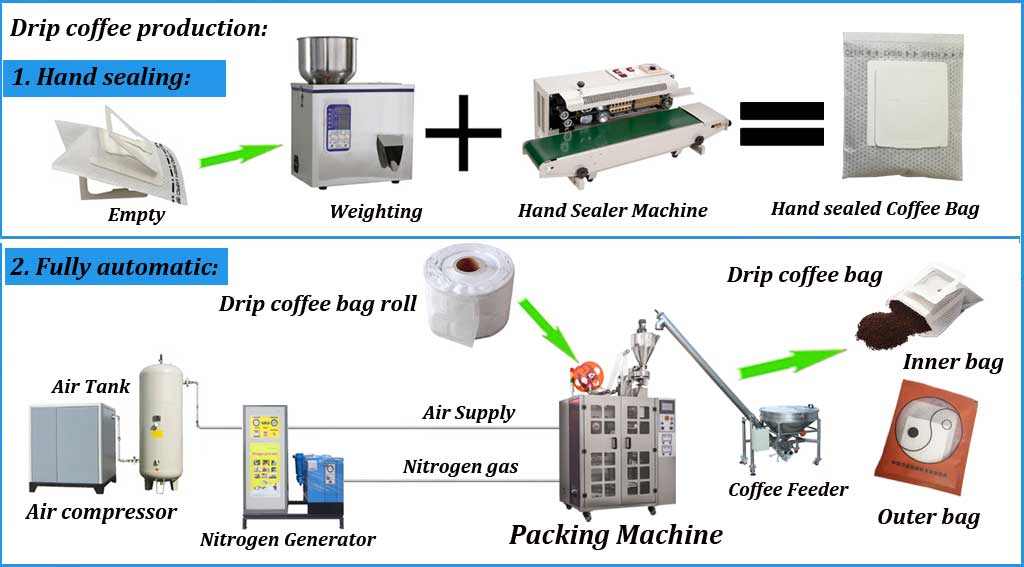

This indonesia coffee drip bags packaging machine with outer package is suitable for Drip coffee bag with outer envelope, with Pictures for details, and Video below:

|

Technical data for Indonesia coffee drip bags packaging machine with outer package: |

|

|

Type: |

Drip coffee packing machine Series |

|

Product model: |

H19D |

|

Product name: |

Indonesia coffee drip bag packaging machine |

|

Bag type: |

3 side sealing |

|

Outer Bag size: |

L:85~120mm,W:75~100mm (Film width 200mm, Bag size: 120*100mm) |

|

Inner Bag size: |

L:50~75mm, W:50~90mm (Filter paper width 180mm, Bag size: 90*75mm) |

|

Packing speed: |

40~60 bags/min |

|

Filling range: |

5~15g; accuracy:≦±0.1g/bag |

|

Measuring: |

Volumetric cup |

|

Inner Packing material |

Drip coffee filter bag film in roll; Nylon filter mesh |

|

Outer packing material |

Kraft paper/aluminum coating; PE/aluminum coating; PE film |

|

Sealing method: |

Ultrasonic sealing and cutting for inner bag; Outer Bag by heat Sealing. |

|

Power: |

Single phase, 220V, 50HZ, 1.5KW |

|

Weight: |

600KG |

|

Dimension (L*W*H): |

1200*900*1900mm |

3. The packaging materials for outer bag is Kraft paper bag or PE bag with aluminum foil, For more details, please kindly contact us.

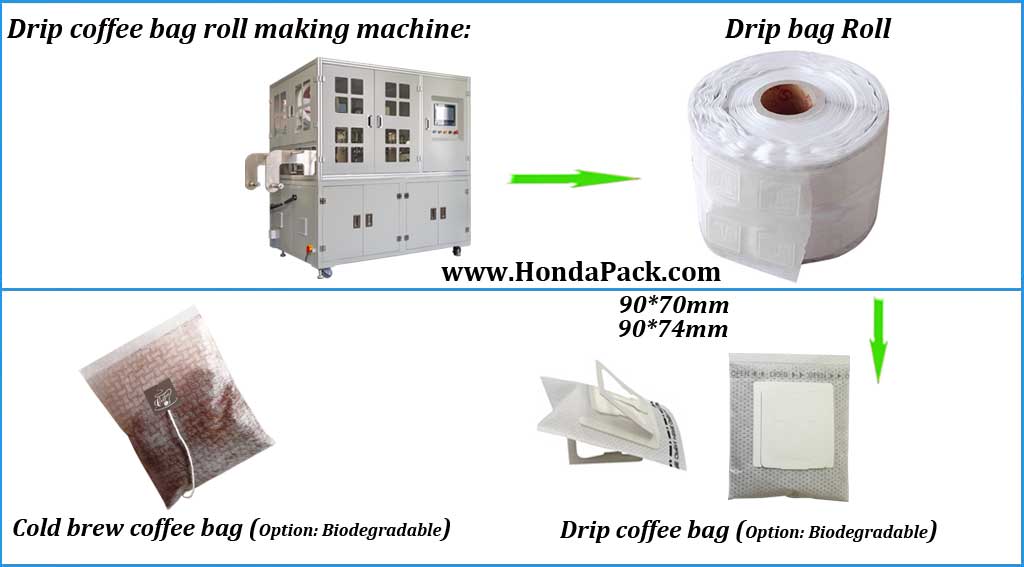

4. Here shows how the drip coffee bag film is made:

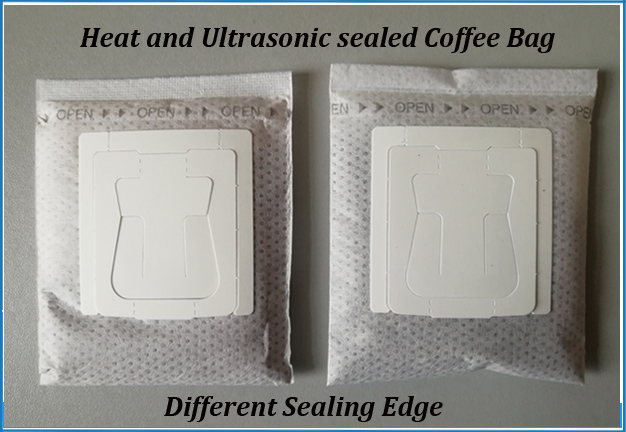

5. The main difference between heat sealing and ultrasonic sealed drip coffee bag is in Sealing Edge of Inner bag. For more details, please kindly contact us.

6. The standard packing for shipping we used is the Plywood Case with plastic film wrapping inside:

7. Nitrogen gas generator: Can supply the Nitrogen gas so that can be injected into drip coffee bag to extend coffee shelf life and keep coffee fresh. For more details, kindly contact for more details.

8. Here shows the working video of drip coffee bag packaging machine:

Except this video, welcome to click here to see more working video.

Feature of drip coffee bag packaging machine:

1. Outer bag sealing is controlled by the stepper motor, ensuring accurate and stable bag length positioning.

2. Adopts PID temperature controller for more accurate temperature adjustment.

3. Adopts PLC control system, touch screen color monitor device, machine is very easy to operate.

4. It can make inner and outer bag in same time automatically, which would highly improve the working efficiency.

5. The process of bag making measuring, filling, sealing, cutting, logo positioning, counting can be finished automatically.

6. All parts in direct contact with products are made of SUS304 stainless steel, ensuring reliable products output conforming to GMP standard.

7. Some parts of the cylinder are imported, ensuring the accuracy and stability of performance.

8. Adopts automatic conveyor system.

9. Machine reserved a connector to link with Nitrogen gas generator so that it can flush the nitrogen into bag to extend product shelf life.

10. Optional devices: Date code printer, nitrogen gas generator, etc.