Product

Contact Us

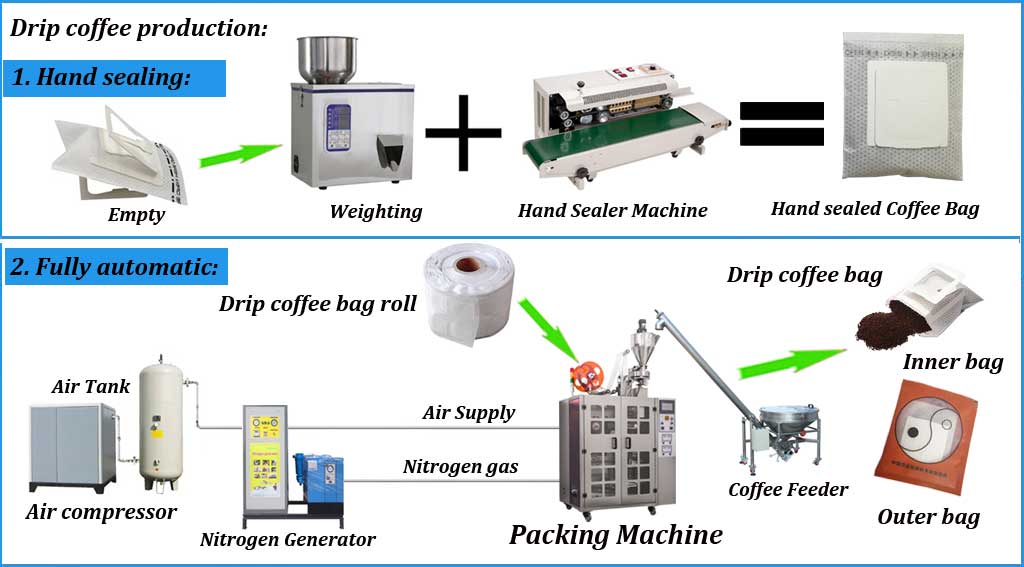

Drip coffee filter paper bag packaging machine with Auger Screw as filling system is suitable for Drip coffee bag with outer envelope, available with fine ground coffee like Brazilian coffee, Guatemala coffee, Honduras coffee, Villa coffee and Arabica coffee, etc, and other small granule products.

To meet the market demand for fine ground coffee, similar as espresso, Turkish coffee, etc, this drip coffee filter paper bag packaging machine is specially designed screw feeding technology, combined with high-precision metering and dust-proof sealing structure to ensure the stability, accuracy and hygiene of fine coffee powder during packaging.

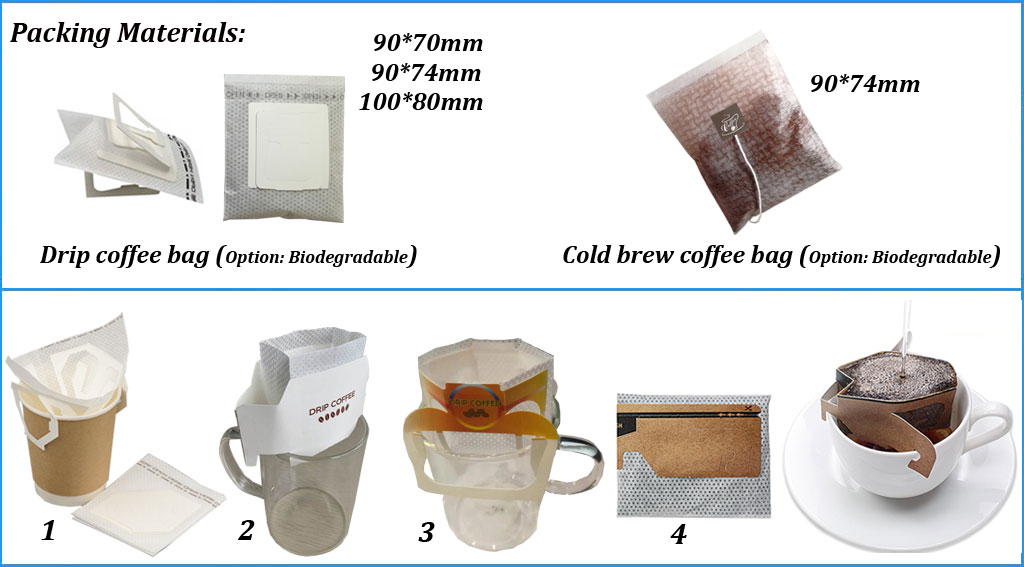

2. Type of drip coffee bag: People from whole world used drip coffee bag between 90*74mm and 90*70mm because the drip coffee bag materials is a kind of standard products for packing machine.

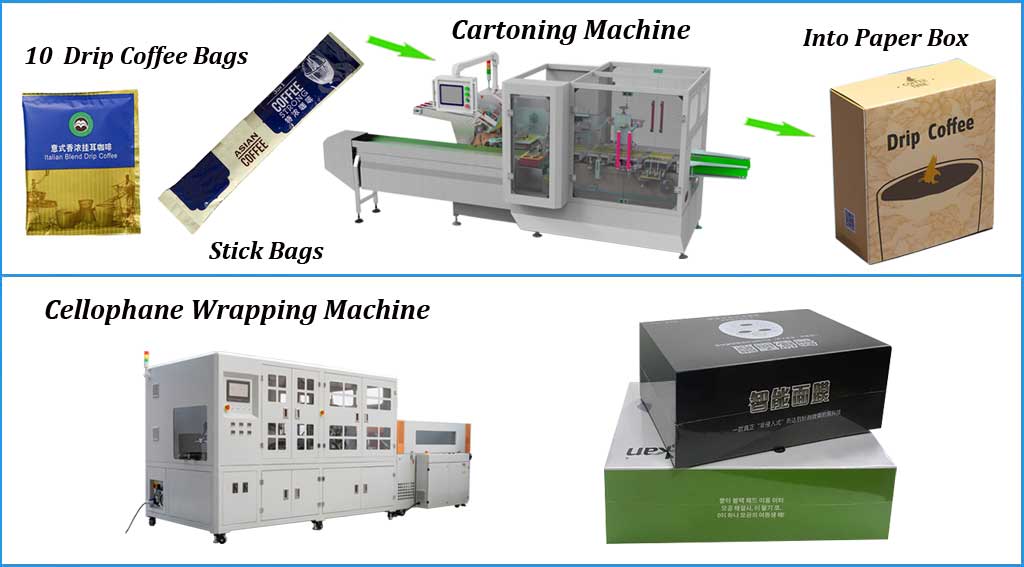

3. The packaging materials for outer bag is Kraft paper bag or PE bag with aluminum foil, For more details, please kindly contact us.

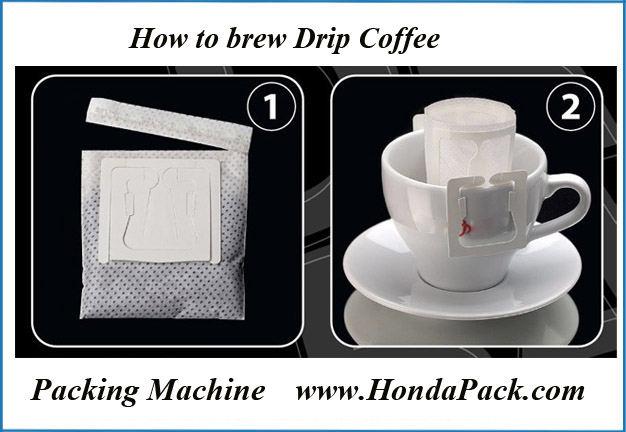

4. Here shows how to brew the drip coffee bag with a cup and a bottle of hot water.

5. The main difference between heat sealing and ultrasonic sealed drip coffee bag is in Sealing Edge of Inner bag. For more details, please kindly contact us.

6. The standard packing for shipping we used is the Plywood Case with plastic film wrapping inside:

7. Nitrogen gas generator: Can supply the Nitrogen gas so that can be inject into drip coffee bag to extend coffee shelf life and keep coffee fresh. For more details, kindly contact for more details.

8. Here shows the working video of drip coffee bag packaging machine: Except this video, welcome to click here to see more working video.

Standard technical data of drip coffee bag packaging machine:

|

Type: |

Drip coffee packing machine Series |

|

Product model: |

C19DF |

|

Product name: |

Drip coffee filter paper bag packaging machine with Auger Screw as filling system |

|

Bag type: |

3 side sealing |

|

Outer Bag size: |

L:85~120mm,W:75~100mm (Film width 200mm, Bag size: 120*100mm) |

|

Inner Bag size: |

L:50~75mm, W:50~90mm (Filter paper width 180mm, Bag size: 90*75mm) |

|

Packing speed: |

40~60 bags/min |

|

Filling range: |

5~15g; accuracy:≦±0.1g/bag |

|

Measuring: |

Auger screw filler |

|

Inner Packing material |

Drip Coffee Bag filter paper; Nylon filter mesh, nonwoven coffee bag with thread and tag |

|

Outer packing material |

Kraft paper/aluminum coating; PE/aluminum coating; PE film |

|

Sealing method: |

Ultrasonic sealing and cutting for inner bag; Outer Bag by heat Sealing. |

|

Power: |

Single phase, 220V, 50HZ, 1.5KW |

|

Weight: |

600KG |

|

Dimension (L*W*H): |

1200*900*1900mm |

Feature of drip coffee bag packaging machine with auger screw as filling system:

1. Auger screw as filling system with precise adaptation for fine coffee powder:

1.1 The equipment adopts a customized screw structure, which realizes

the stable delivery of fine coffee powder through rotation and

propulsion, avoiding the problems of agglomeration, dust or blockage

easily caused by traditional vibration feeding.

1.2 The screw

speed and feeding amount are adjustable, which can adapt to fine coffee

powders of different mesh sizes (such as 120-200 mesh), ensuring smooth

feeding and measurement error ≤±0.1G.

2. High-precision measurement to ensure quality consistency

2.1 Equipped with a high-sensitivity weighing sensor, real-time

monitoring of packaging weight, combined with a dynamic compensation

algorithm, automatically adjusts the feeding speed to ensure the

accurate and stable weight of each bag of coffee powder.

2.2 Supports preset multi-specification packaging capacity (such as 10g, 12g, etc.) to meet different market needs.

3. Dust-proof sealing design to reduce loss and pollution:

3.1 Fully enclosed silo and feeding channel, with negative pressure

dust removal system, effectively suppress the flying of ultra coffee

powder, avoid waste of raw materials and pollution in the workshop.

3.2 Key components are made of food-grade stainless steel, with smooth

and easy-to-clean surface, in line with food safety standards.

4. Automation integration to improve production efficiency:

4.1 Integrated automatic bagging, filling, sealing, coding and other

functions, supporting single-station or multi-station linkage,

single-machine production capacity can reach 30-60 bags/minute

(depending on packaging specifications).

4.2 Touch screen operation

interface, support quick parameter setting and fault self-diagnosis,

reduce the need for manual intervention.

Product Name:C19DF Drip coffee filter paper bag packaging machine with Auger Screw as filling system