Cellophane wrapping machine installation, precaution and maintenance

Date:2023-04-04 Categories:Blog

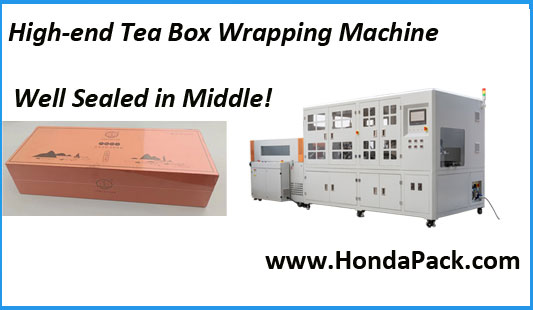

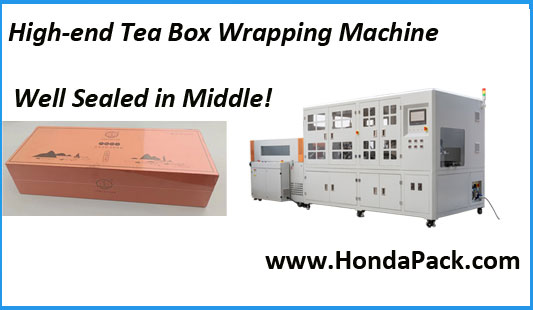

Here is the installation, precaution and maintenance for automatic cellophane wrapping machine with heat shrinking machine for tea box.

1. Precautions for installation of automatic cellophane wrapping machine with heat tunnel shrink wrap machine for tea box.

1. The heat shrinking machine and the winding machine consume a lot of power, so the power of the input power must be greater than the nominal power on the nameplate of the shrinking machine, otherwise it is easy to burn the circuit or electrical components.

2. Like a baler, the machine must be reliably grounded to protect personal safety.

3. Each machine is attached with a power cable when it leaves the factory. The lead part of the terminal has the identification symbol of the power supply. It must be connected correctly. Operation in violation of regulations may cause electric shock.

4. When the specified voltage of the machine is a three-phase 380V power supply, the neutral line must be input at the same time, that is, the standard three-phase four-wire system and other packaging equipment are also like vacuum packaging machines. Otherwise, the machine cannot work normally, and it is easy to burn the internal electrical components.

5. The machine must be installed horizontally, otherwise the service life of the electric heating tube will be shortened. For machines conveyed by mesh belts, their inclined installation will cause the conveyor belt to be off-center.

6. When the machine has been used continuously for more than three months, the heat-resistant wires in the shrinking chamber should be checked and replaced as appropriate according to their aging degree.

⒎When the machine is working, the operator's palm and other parts are not allowed to come into contact with the running parts of the machine, especially the temperature inside the shrinking chamber is extremely high, which is easy to burn.

8. After the packaging work is completed, the heating switch should be turned off first, and the conveying motor and fan motor should continue to run for about 10 minutes, and then cut off the entire power supply.

Second, the maintenance of heat shrinking machine for tea box:

As a commonly used equipment in the production industry, heat shrinking machines are widely used, such as food, beverages, daily necessities, etc. The heat shrinking machine also needs routine maintenance to ensure the smooth operation of the shrinking machine. It is very important to lubricate the heat shrinking machine in use. For example, the vacuum packaging machine needs to change the vacuum pump oil regularly, and the sewing machine needs to be refueled regularly. Similarly, the lubrication of the shrinking machine is also essential.

During the work of the heat shrinking machine, it is necessary to lubricate the various parts of the equipment, the regular cleaning of the parts and the daily basic maintenance. The lubrication of the heat shrinking machine equipment is the prerequisite for the equipment to work, so the lubrication of the various parts of the PE film shrinking machine must be in place It is necessary to pay attention to the working principle of the equipment. The heat shrinking machine is a commonly used equipment. It is necessary to regularly lubricate the gear meshes, the oil injection holes of the bearings with seats and the moving parts. Once per shift, it must be done day after day. The transmission belt of the heat shrinking machine is the most easily worn equipment in the work. When filling the heat shrinking machine with lubricating oil, please be careful not to drop the oil on the heat shrinking machine transmission belt to prevent slipping and loss of the belt or the premature failure of the belt. Aging damage.

Among the working parts of the heat shrinking machine, the reducer is an important component of the equipment. It is strictly forbidden to run the reducer without oil. After 300 hours of operation for the first time, clean the inside and replace with new oil, and then change the oil every 2500 hours of work. It is a high-tech equipment, but it also needs to pay attention to the way of operation in the work. There are many precautions in the lubrication of the parts of the heat shrinking machine.

Therefore, paying attention when the cellophane wrapping machine is working is the prerequisite for maintaining the equipment and working normally.

3. Cellophane wrapping machine strengthens automatic packaging and is more efficient:

People's living standards are getting higher and higher, and their material needs are constantly being pursued. At the same time, a large number of heat shrinking machines have proved the convenience brought by automation and high efficiency, and only high-efficiency production can satisfy the domestic commodity market. In order to make the products unique and innovative, we are more focused on the technology of heat shrinking machines, so as to start to develop for the satisfaction of the public, and to be exquisite in details. Only in this way can we not be eliminated in the fierce competition environment. So that it is handy and more pioneering for the development of the packaging machine industry.

Thermal shrink wrapping machine are the most used equipment in mechanical automation. If we want to reach the peak of heat shrinking machine technology development, then this is the result of countless colleagues and innovative efforts. The rapid trend in the heat shrinking machine market is expected to come earlier, which is also a manifestation of commodity and economic development. In the face of the pursuit of numerous products, improving the value of equipment must be able to win recognition and favor.

In the face of countless enterprises and users, the heat shrinkable machine must strive to achieve all aspects, so as to bring its greatest benefits. As a new type of high-efficiency equipment in the industry, the heat shrinking machine has quickly entered the development track of the industry because of the support of the market. If there is no market support, it will affect its own development and be unfavorable. It will also be eliminated and abandoned by people like other commodities. Therefore, the packaging can be more efficient after the heat shrinking machine is enhanced with automation.

4. How to deal with the waste of heat shrink packaging wrapping machine:

Using the heat shrinking machine for a long time will generate a lot of waste, which has been reflected by many customers and is harmful to the environment or staff. So for this problem, how to effectively solve it?

At the beginning, it was said that shrink packaging materials pollute the environment a lot. In fact, this statement is wrong. Most of the packaging films of shrink packaging machines use PE packaging films or pof packaging films. High, generally speaking, the recyclability rate is relatively high, so even if it is discarded, this material can be recycled, and the pollution to the environment is not so serious.

Because the shrink packaging machine uses shrink film for packaging, we usually throw the packaging film away when we unpack the product. It is not like the handbag, gift box and other things that can be packaged after packaging the item. Therefore, many people think that the use of shrinking machines has brought great convenience to our lives, but it has caused serious pollution, which does not conform to the theme of sustainable development and green development advocated now.

So according to this statement, is the shrink packaging machine going to be idle? of course not. Mag Machinery is here to tell you that the environmental pollution caused by the shrinking machine is not so serious. It is impossible to say that it does not pollute the environment at all. It is impossible for any type of machinery to be completely pollution-free to the environment. It can be said that the pollution to the environment is relatively light.

We know that a shrink machine is a device that shrinks and heats a film with shrinkage properties to achieve packaging products. This kind of packaging machinery products is mainly used to improve the exhibition and sale of products, and at the same time play a role in moisture-proof and pollution-proof for the products. When the products are impacted by external forces, they can also protect the products to a certain extent; Food industry, beverage industry, furniture industry, hardware industry and other applications are very extensive.

5. Working principle of heat shrinkable film machine

The working principle of the heat shrinking machine is simple: it is to use the principle of heat shrinkage of the heat shrinkable film. The original molecules are constantly changing due to the irregular arrangement. Under the heat radiation such as infrared rays, the plastic molecules will be re-closed. Arrangement, so that the area of the original shrink film is continuously reduced, so that the shrink film is tightly bound to the surface of the product, so as to realize the work of shrink packaging.

The main classification of heat shrinkable film machine:

According to the shrink film: PE heat shrinkable film packaging machine and POF heat shrinkable film packaging machine;

PE heat shrinkable film packaging machine heat shrinkable film packaging machine

According to the heating method: quartz tube heating and stainless steel heating;

According to the speed regulation method: electronic speed regulation and frequency conversion speed regulation.

Main features of using heat shrinking machine:

During the shrinking process, it does not affect the quality of the package, but can shrink quickly and perfectly. The packaged product can be sealed, moisture-proof, and impact-proof, and is suitable for tight packaging and pallet packaging of multiple items.

The main scope of use of the shrinking machine:

Glass bottles, styrofoam, cartons, toys, electronics, electrical appliances, stationery, books, records, hardware tools, daily necessities, medicines, cosmetics, beverages, fruits, commemorative labels and other items packaging.

6. Daily maintenance of shrink wrapping tunnel machine:

As a commonly used equipment in the production industry, heat shrink packaging machines are widely used, such as food, beverages, daily necessities, etc. A good shrinking machine also needs daily maintenance to ensure the smooth operation of the shrinking machine. It is very important to lubricate the machine during use. For example, the vacuum packaging machine needs to change the vacuum pump oil regularly, and the sewing machine needs to be refueled regularly. Similarly, the lubrication of the shrinking machine is also essential: the heat shrink packaging machine must lubricate the various parts of the equipment during work. Regular cleaning of parts and daily basic maintenance, lubrication of heat shrink packaging machine equipment is the premise of equipment work, so when lubricating each part of heat shrink packaging machine, we must pay attention to the working principle of the equipment, heat shrink packaging machine It is a commonly used equipment. It is necessary to regularly lubricate the gear meshes, the oil injection holes of the bearings with seats, and the moving parts. Once per shift, it must be done day after day, and the transmission belt of the heat shrink packaging machine is the most important part of the work. For equipment that is easy to wear, when adding lubricating oil to the heat shrink packaging machine, please be careful not to drop the oil on the transmission belt to prevent slipping and loss or premature aging of the belt, and slow down in the working parts of the heat shrink packaging machine The reducer is an important component of the equipment. It is strictly forbidden to run the reducer without oil. After the first 300 hours of operation, clean the interior and replace it with new oil, and then change the oil every 2500 hours of work. It is also necessary to pay attention to the way of operation. There are many precautions in the lubrication of the parts of the heat shrink packaging machine. Therefore, attention during work is the prerequisite for maintaining the equipment and normal work.

Xiamen HondaPack is located in the beautiful coastal city-Xiamen City, Fujian Province. The company mainly focuses on manufacturing, research and development and sales, tea bag packing machine, Drip coffee packaging machine, tea bag tagging machine, stand up pouch filling and sealing machine, tea box wrapping and shrinking machine, muli lane stick packing machine, etc, mainly for tea and coffee company and factory.

The company has always adhered to the tenet of "quality first, customer first, high-quality service, and abiding by the contract". With high-quality products, good reputation, and high-quality service, the products sell well all over the country. The HondaPack company has advanced equipment and technology. Over the past few years, our company has accumulated rich manufacturing experience. In recent years, it has strengthened the strict control of product quality, improved the cost performance of products, and made customers truly feel the economy, environmental protection and excellent quality.

7. Precautions for automatic cellophane wrapping machine with heat tunnel thermal shrink wrap machine:

1. The heat shrinking machine is the same as the winding machine because it consumes a lot of power, so the power of the input power supply must be greater than the nominal power on the nameplate of the shrinking machine, otherwise it is easy to burn the circuit or electrical components.

2. Like a baler, the machine must be reliably grounded to protect personal safety.

3. Each machine is attached with a power cable when it leaves the factory, and the lead part of the terminal has the identification symbol of the power supply, which must be connected correctly, and the operation in violation of regulations may cause electric shock.

4. When the specified voltage of the machine is a three-phase 380V power supply, the zero line must be input at the same time, that is, the standard three-phase four-wire system and other packaging equipment are also like vacuum packaging machines. Otherwise, the machine cannot work normally, and it is easy to burn the internal electrical components.

5. The machine must be installed horizontally, otherwise the service life of the electric heating tube will be shortened. For machines conveyed by mesh belts, their inclined installation will cause the conveyor belt to be off-center.

6. When the machine has been used continuously for more than three months, the heat-resistant wires in the shrinking chamber should be checked and replaced as appropriate according to their aging degree.

7. When the machine is working, the operator's palm and other parts are not allowed to come into contact with the running parts of the machine, especially the temperature inside the shrinking chamber is extremely high, which is easy to burn.

8. After the packaging work is completed, the heating switch should be turned off first, and the conveying motor and fan motor should continue to run for about 10 minutes, and then cut off the entire power supply.

The main operating procedures of automatic cellophane wrapping machine with heat tunnel thermal shrink wrap machine:

a) Turn on the power switch to turn on the power. Start the conveyor belt, preheat for about 5 minutes, and turn on the fan switch. At this time, according to the size of the item and the thickness of the film, adjust the temperature adjustment knob and the conveying speed of the upper and lower chambers, and after debugging to meet the use requirements, shrink packaging can be carried out.

b) In the actual situation, if there are too many wrinkles after shrinkage, you can reduce the conveying speed or increase the heating temperature but not more than seven grades. On the contrary, if excessive shrinkage occurs, you can reduce the temperature or increase the conveying speed but not more than seven grades. (voltage in the case of 220V).

c) After the operation, turn off the heating switch first, let the conveying motor and the hot air motor continue to run for about 10 minutes, and then cut off the entire power supply.

1. Precautions for installation of automatic cellophane wrapping machine with heat tunnel shrink wrap machine for tea box.

1. The heat shrinking machine and the winding machine consume a lot of power, so the power of the input power must be greater than the nominal power on the nameplate of the shrinking machine, otherwise it is easy to burn the circuit or electrical components.

2. Like a baler, the machine must be reliably grounded to protect personal safety.

3. Each machine is attached with a power cable when it leaves the factory. The lead part of the terminal has the identification symbol of the power supply. It must be connected correctly. Operation in violation of regulations may cause electric shock.

4. When the specified voltage of the machine is a three-phase 380V power supply, the neutral line must be input at the same time, that is, the standard three-phase four-wire system and other packaging equipment are also like vacuum packaging machines. Otherwise, the machine cannot work normally, and it is easy to burn the internal electrical components.

5. The machine must be installed horizontally, otherwise the service life of the electric heating tube will be shortened. For machines conveyed by mesh belts, their inclined installation will cause the conveyor belt to be off-center.

6. When the machine has been used continuously for more than three months, the heat-resistant wires in the shrinking chamber should be checked and replaced as appropriate according to their aging degree.

⒎When the machine is working, the operator's palm and other parts are not allowed to come into contact with the running parts of the machine, especially the temperature inside the shrinking chamber is extremely high, which is easy to burn.

8. After the packaging work is completed, the heating switch should be turned off first, and the conveying motor and fan motor should continue to run for about 10 minutes, and then cut off the entire power supply.

Second, the maintenance of heat shrinking machine for tea box:

As a commonly used equipment in the production industry, heat shrinking machines are widely used, such as food, beverages, daily necessities, etc. The heat shrinking machine also needs routine maintenance to ensure the smooth operation of the shrinking machine. It is very important to lubricate the heat shrinking machine in use. For example, the vacuum packaging machine needs to change the vacuum pump oil regularly, and the sewing machine needs to be refueled regularly. Similarly, the lubrication of the shrinking machine is also essential.

During the work of the heat shrinking machine, it is necessary to lubricate the various parts of the equipment, the regular cleaning of the parts and the daily basic maintenance. The lubrication of the heat shrinking machine equipment is the prerequisite for the equipment to work, so the lubrication of the various parts of the PE film shrinking machine must be in place It is necessary to pay attention to the working principle of the equipment. The heat shrinking machine is a commonly used equipment. It is necessary to regularly lubricate the gear meshes, the oil injection holes of the bearings with seats and the moving parts. Once per shift, it must be done day after day. The transmission belt of the heat shrinking machine is the most easily worn equipment in the work. When filling the heat shrinking machine with lubricating oil, please be careful not to drop the oil on the heat shrinking machine transmission belt to prevent slipping and loss of the belt or the premature failure of the belt. Aging damage.

Among the working parts of the heat shrinking machine, the reducer is an important component of the equipment. It is strictly forbidden to run the reducer without oil. After 300 hours of operation for the first time, clean the inside and replace with new oil, and then change the oil every 2500 hours of work. It is a high-tech equipment, but it also needs to pay attention to the way of operation in the work. There are many precautions in the lubrication of the parts of the heat shrinking machine.

Therefore, paying attention when the cellophane wrapping machine is working is the prerequisite for maintaining the equipment and working normally.

3. Cellophane wrapping machine strengthens automatic packaging and is more efficient:

People's living standards are getting higher and higher, and their material needs are constantly being pursued. At the same time, a large number of heat shrinking machines have proved the convenience brought by automation and high efficiency, and only high-efficiency production can satisfy the domestic commodity market. In order to make the products unique and innovative, we are more focused on the technology of heat shrinking machines, so as to start to develop for the satisfaction of the public, and to be exquisite in details. Only in this way can we not be eliminated in the fierce competition environment. So that it is handy and more pioneering for the development of the packaging machine industry.

Thermal shrink wrapping machine are the most used equipment in mechanical automation. If we want to reach the peak of heat shrinking machine technology development, then this is the result of countless colleagues and innovative efforts. The rapid trend in the heat shrinking machine market is expected to come earlier, which is also a manifestation of commodity and economic development. In the face of the pursuit of numerous products, improving the value of equipment must be able to win recognition and favor.

In the face of countless enterprises and users, the heat shrinkable machine must strive to achieve all aspects, so as to bring its greatest benefits. As a new type of high-efficiency equipment in the industry, the heat shrinking machine has quickly entered the development track of the industry because of the support of the market. If there is no market support, it will affect its own development and be unfavorable. It will also be eliminated and abandoned by people like other commodities. Therefore, the packaging can be more efficient after the heat shrinking machine is enhanced with automation.

4. How to deal with the waste of heat shrink packaging wrapping machine:

Using the heat shrinking machine for a long time will generate a lot of waste, which has been reflected by many customers and is harmful to the environment or staff. So for this problem, how to effectively solve it?

At the beginning, it was said that shrink packaging materials pollute the environment a lot. In fact, this statement is wrong. Most of the packaging films of shrink packaging machines use PE packaging films or pof packaging films. High, generally speaking, the recyclability rate is relatively high, so even if it is discarded, this material can be recycled, and the pollution to the environment is not so serious.

Because the shrink packaging machine uses shrink film for packaging, we usually throw the packaging film away when we unpack the product. It is not like the handbag, gift box and other things that can be packaged after packaging the item. Therefore, many people think that the use of shrinking machines has brought great convenience to our lives, but it has caused serious pollution, which does not conform to the theme of sustainable development and green development advocated now.

So according to this statement, is the shrink packaging machine going to be idle? of course not. Mag Machinery is here to tell you that the environmental pollution caused by the shrinking machine is not so serious. It is impossible to say that it does not pollute the environment at all. It is impossible for any type of machinery to be completely pollution-free to the environment. It can be said that the pollution to the environment is relatively light.

We know that a shrink machine is a device that shrinks and heats a film with shrinkage properties to achieve packaging products. This kind of packaging machinery products is mainly used to improve the exhibition and sale of products, and at the same time play a role in moisture-proof and pollution-proof for the products. When the products are impacted by external forces, they can also protect the products to a certain extent; Food industry, beverage industry, furniture industry, hardware industry and other applications are very extensive.

5. Working principle of heat shrinkable film machine

The working principle of the heat shrinking machine is simple: it is to use the principle of heat shrinkage of the heat shrinkable film. The original molecules are constantly changing due to the irregular arrangement. Under the heat radiation such as infrared rays, the plastic molecules will be re-closed. Arrangement, so that the area of the original shrink film is continuously reduced, so that the shrink film is tightly bound to the surface of the product, so as to realize the work of shrink packaging.

The main classification of heat shrinkable film machine:

According to the shrink film: PE heat shrinkable film packaging machine and POF heat shrinkable film packaging machine;

PE heat shrinkable film packaging machine heat shrinkable film packaging machine

According to the heating method: quartz tube heating and stainless steel heating;

According to the speed regulation method: electronic speed regulation and frequency conversion speed regulation.

Main features of using heat shrinking machine:

During the shrinking process, it does not affect the quality of the package, but can shrink quickly and perfectly. The packaged product can be sealed, moisture-proof, and impact-proof, and is suitable for tight packaging and pallet packaging of multiple items.

The main scope of use of the shrinking machine:

Glass bottles, styrofoam, cartons, toys, electronics, electrical appliances, stationery, books, records, hardware tools, daily necessities, medicines, cosmetics, beverages, fruits, commemorative labels and other items packaging.

6. Daily maintenance of shrink wrapping tunnel machine:

As a commonly used equipment in the production industry, heat shrink packaging machines are widely used, such as food, beverages, daily necessities, etc. A good shrinking machine also needs daily maintenance to ensure the smooth operation of the shrinking machine. It is very important to lubricate the machine during use. For example, the vacuum packaging machine needs to change the vacuum pump oil regularly, and the sewing machine needs to be refueled regularly. Similarly, the lubrication of the shrinking machine is also essential: the heat shrink packaging machine must lubricate the various parts of the equipment during work. Regular cleaning of parts and daily basic maintenance, lubrication of heat shrink packaging machine equipment is the premise of equipment work, so when lubricating each part of heat shrink packaging machine, we must pay attention to the working principle of the equipment, heat shrink packaging machine It is a commonly used equipment. It is necessary to regularly lubricate the gear meshes, the oil injection holes of the bearings with seats, and the moving parts. Once per shift, it must be done day after day, and the transmission belt of the heat shrink packaging machine is the most important part of the work. For equipment that is easy to wear, when adding lubricating oil to the heat shrink packaging machine, please be careful not to drop the oil on the transmission belt to prevent slipping and loss or premature aging of the belt, and slow down in the working parts of the heat shrink packaging machine The reducer is an important component of the equipment. It is strictly forbidden to run the reducer without oil. After the first 300 hours of operation, clean the interior and replace it with new oil, and then change the oil every 2500 hours of work. It is also necessary to pay attention to the way of operation. There are many precautions in the lubrication of the parts of the heat shrink packaging machine. Therefore, attention during work is the prerequisite for maintaining the equipment and normal work.

Xiamen HondaPack is located in the beautiful coastal city-Xiamen City, Fujian Province. The company mainly focuses on manufacturing, research and development and sales, tea bag packing machine, Drip coffee packaging machine, tea bag tagging machine, stand up pouch filling and sealing machine, tea box wrapping and shrinking machine, muli lane stick packing machine, etc, mainly for tea and coffee company and factory.

The company has always adhered to the tenet of "quality first, customer first, high-quality service, and abiding by the contract". With high-quality products, good reputation, and high-quality service, the products sell well all over the country. The HondaPack company has advanced equipment and technology. Over the past few years, our company has accumulated rich manufacturing experience. In recent years, it has strengthened the strict control of product quality, improved the cost performance of products, and made customers truly feel the economy, environmental protection and excellent quality.

7. Precautions for automatic cellophane wrapping machine with heat tunnel thermal shrink wrap machine:

1. The heat shrinking machine is the same as the winding machine because it consumes a lot of power, so the power of the input power supply must be greater than the nominal power on the nameplate of the shrinking machine, otherwise it is easy to burn the circuit or electrical components.

2. Like a baler, the machine must be reliably grounded to protect personal safety.

3. Each machine is attached with a power cable when it leaves the factory, and the lead part of the terminal has the identification symbol of the power supply, which must be connected correctly, and the operation in violation of regulations may cause electric shock.

4. When the specified voltage of the machine is a three-phase 380V power supply, the zero line must be input at the same time, that is, the standard three-phase four-wire system and other packaging equipment are also like vacuum packaging machines. Otherwise, the machine cannot work normally, and it is easy to burn the internal electrical components.

5. The machine must be installed horizontally, otherwise the service life of the electric heating tube will be shortened. For machines conveyed by mesh belts, their inclined installation will cause the conveyor belt to be off-center.

6. When the machine has been used continuously for more than three months, the heat-resistant wires in the shrinking chamber should be checked and replaced as appropriate according to their aging degree.

7. When the machine is working, the operator's palm and other parts are not allowed to come into contact with the running parts of the machine, especially the temperature inside the shrinking chamber is extremely high, which is easy to burn.

8. After the packaging work is completed, the heating switch should be turned off first, and the conveying motor and fan motor should continue to run for about 10 minutes, and then cut off the entire power supply.

The main operating procedures of automatic cellophane wrapping machine with heat tunnel thermal shrink wrap machine:

a) Turn on the power switch to turn on the power. Start the conveyor belt, preheat for about 5 minutes, and turn on the fan switch. At this time, according to the size of the item and the thickness of the film, adjust the temperature adjustment knob and the conveying speed of the upper and lower chambers, and after debugging to meet the use requirements, shrink packaging can be carried out.

b) In the actual situation, if there are too many wrinkles after shrinkage, you can reduce the conveying speed or increase the heating temperature but not more than seven grades. On the contrary, if excessive shrinkage occurs, you can reduce the temperature or increase the conveying speed but not more than seven grades. (voltage in the case of 220V).

c) After the operation, turn off the heating switch first, let the conveying motor and the hot air motor continue to run for about 10 minutes, and then cut off the entire power supply.