Contact

Tel: +8613376983289

E-mail: sgpeter@ xmsgjx.com

ADD: No.185, Xinqian Road, Jimei District, Xiamen, China

Coffee and tea production line

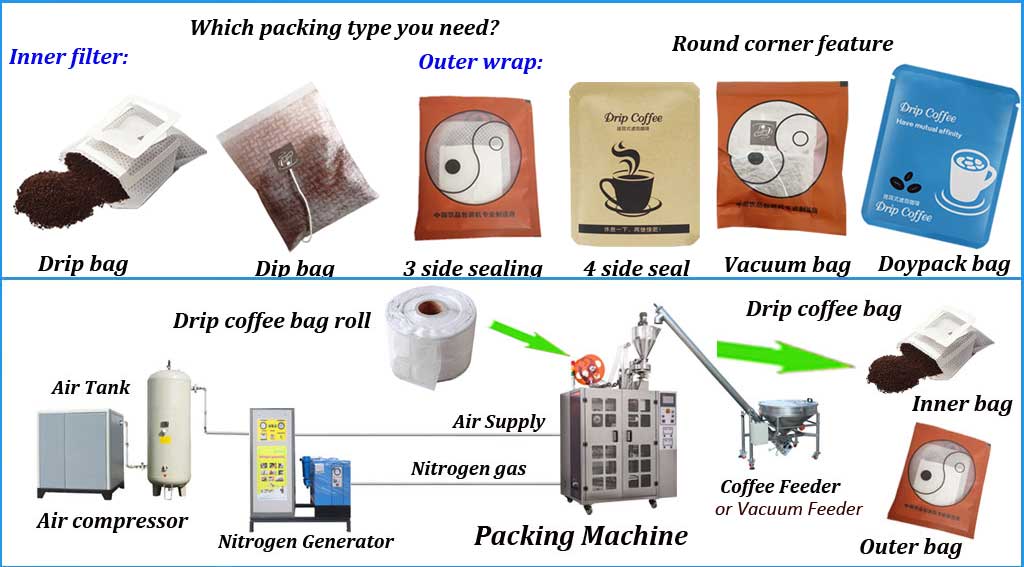

Tea bag production line like green tea production line, and drip coffee production line is packaging line for tea company and coffee roaster.Drip coffee pouch packing machine

1. What is the equipment of a packaging line?

The packaging line will consist of filling equipment, weighing device, sealing machinery, wrapping machine, labeling equipment, with other packaging machines in tea and coffee industry.